Turbomachinery Analysis Services by CFD Experts

The necessity to develop efficient power generating devices requires deeper understanding on performance contributing factors and fine tuning them for the next generation power plants.

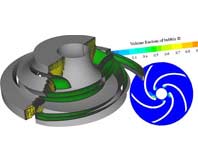

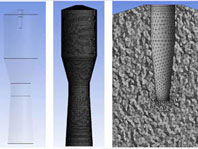

We specialize in providing solutions for turbomachinery design and performance optimization through computer aided simulations. With crucial information on flow behavior inside turbines, pumps and compressors, engineers can quickly optimize the design constraints such as blade geometry, flow angles, mass flow rate and pressure drop to improve the performance right from the early stage of the design.

Simulation driven design for turbomachinery helps in identifying key design constraints affecting the device performance and subsequently provides the opportunity to convert those constraints to alternative and efficient design concepts. With virtual simulations, the number of prototyping trials is reduced considerably. Through reduction in physical trials, we help turbomachinery designers to reduce the turn-around time for development as well as the associated costs and gain a competitive edge in the market.

Domain Expertise

Our CFD analysts specialize in providing design solutions for turbomachinery to evaluate blade design, predict effects of high temperature fluid flow and pressure drops as well as simulate the possibility of cavitation in devices like turbines, compressors, pumps, fans and blowers.

Software We Use: