CFD Analysis for Engine Design: Fuelling Innovation

Posted by: Mehul Patel | Posted on: September 12th, 2014

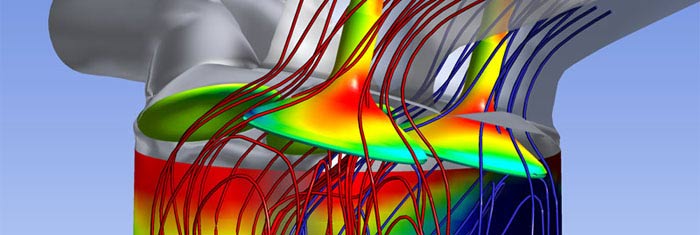

CFD- computational fluid dynamics is a tool that can furnish designers with detailed and useful information, which can be fed back into the design to develop a well engineered product. It is widely used across the automotive industry for automobile design and development – Specifically for automobile engine design. In CFD analysis, a mesh that represents an engine in the form of a 3D geometry – including all the sub models for fuel injection, turbulence, chemistry and combustion, is used to solve the fundamental equations that describe a fluid flow. Using CFD capabilities, engineers can visualize and analyze the moving geometry and its effect on fluid flows and the complex interactions that occur within an engine.

CFD analysis for an automobile engine design can be bifurcated into various levels each being more complex than the previous, namely – port flow analysis, cold flow analysis, IC combustion simulation, and full cycle simulation.

The Procedural Steps to CFD Analysis Include:

- Define the modeling goals

- Develop a 3D geometry

- Set up solver and physical models

- Compute and analyze the solutions

- Evaluate the results and consider revisions in the design

Some areas of concern when it comes to engine design for automobiles include, meeting the legislative requirements, engineering and building the engine to meet fuel consumption and power output requirements and carbon emission regulations. Other challenges faced by an automobile engine design expert include ensuring that the design is durable and of good quality, and also to ensure that if the manufacturer is investing in design and development, then this investment yields good returns.

In order to address all these challenges engineers prefer using CFD tools in the early design stages. This enables quantification of trade-offs such as soot vs NOx, swirl vs. tumble, combustion efficiency vs. pollution formation etc. Besides, using CFD also allows an engineer to fast track the design process by investing more time in design phase as a result saving a lot more time during the validation phase, additionally, it also helps cut down on the prototyping costs.

Enabling Innovation Using CFD Capabilities

The landscapes for the automotive industry are evolving and have become highly competitive. This is why, automobile manufactures need to constantly improve their designs and provide better products to stay in the market. Innovation is the key!

Computational fluid dynamics gives automobile engineers a free hand to make design iterations and experiment more. This creates great scope for innovation and translates into engine designs that perform better and deliver high value.

May be you like to read more about : The Rise of CFD in Building Internal Combustion Engines of Tomorrow

(Image Source: ansys.com)

About Author: Mehul Patel specializes in handling CFD projects for Automobile, Aerospace, Oil and Gas and building HVAC sectors. He works as a CFD consultant with Hi-Tech CFD for the past 5 years and has successfully executed numerous CFD projects of high complexities. He is an expert in turbo-machinery, gas dynamics, Combustion, Fluid Dynamics, multiphase flow analysis, computational fluid dynamics etc.