Optimizing Industrial Drying Systems Using CFD

Posted by: Mehul Patel | Posted on: March 31st, 2015

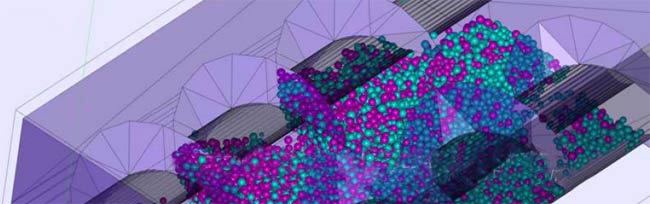

Industrial drying systems are most commonly used in process industries to remove moisture content from the materials. These systems are designed according to the required moisture removal requirement. The working principle of drying systems is purely based on evaporation of liquids from solids.

The application of heat could be direct through hot air, or indirect using remote heating and cooling utilities. A tray dryer is one of the drying systems most commonly employed in industries. It utilizes the flow of hot air around the material being spread across the tray and absorbs moisture through the material through evaporation.

However, one of the major drawbacks of the tray dryer is its inability to maintain uniformity in moisture removal from the end product. This is essentially due to improper airflow circulation mainly due to inadequate flow path design within the chamber. An ideal dryer is one which would remove moisture from the materials uniformly across all the trays arranged.

Read Full Story: Optimizing Industrial Drying Systems Using CFD

About Author: Mehul Patel specializes in handling CFD projects for Automobile, Aerospace, Oil and Gas and building HVAC sectors. He works as a CFD consultant with Hi-Tech CFD for the past 5 years and has successfully executed numerous CFD projects of high complexities. He is an expert in turbo-machinery, gas dynamics, Combustion, Fluid Dynamics, multiphase flow analysis, computational fluid dynamics etc.