Computational Fluid Dynamics (CFD) Simulation Benefits Practical Applications

Posted by: Mehul Patel | Posted on: January 20th, 2013

Benefits and Practical Applications:

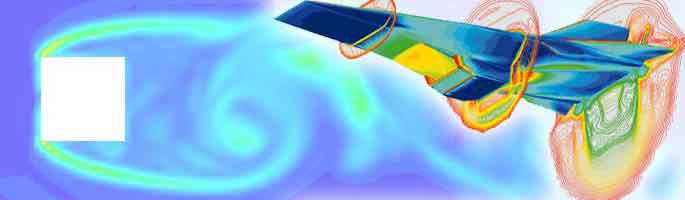

CFD Simulation is also known as CFD modeling and it is engineering based scientific process module which runs on Computational Fluid Dynamics theory and is applied for resolving different fluid flow related problems like flow velocity, density, temperature, and chemical concentrations for any area where flow is present. It’s a numerical method for calculation for nonlinear differential equations describing/relating to fluid flow. CFD simulation is applied in various industries to day in order to achieve flawless product designing by combining computational tools and theory of fluid dynamics.

Industries where CFD Modeling is Applied:

CFD Solution/modeling is used in different industries for different analytical capabilities. Some of the prime industries where CFD simulation is frequently used are Aerospace / Aeronautics, Automotive or Automobile, Building HVAC[(heating, ventilation, and air conditioning), Chemical / Petrochemicals, Energy / Power Generation, Manufacturing / Process Engineering, oil and gas industry, Product Design and Optimization, Oil and gas Industry, and Turbo Machinery, etc. In most of the instances, Computational Fluid Dynamics Modeling is used for deriving most accurate options for designing or the efficiency level of HVAC system.

Practical Advantages of Employing CFD:

The many reasons CFD consulting is being widely used today are as follows:

- CFD foresee performance before adapting or execution in systems

- Without modifying or installing real system or a sample, CFD simulation can forecast which changes in design layout are most vital for improving performance.

- CFD model offers precise and detailed information about heating, ventilation, and air conditioning design parameters

- The advancement in HVAC/IAQ technology need wider and detailed information about the flow within an occupied zone while CFD meets the goal better than any other theoretical or experimental methods.

- CFD modeling saves cost and turnaround time and it procures reliable results. This is the reason CFD analysis report is accounted as completely reliable.

Where can be CFD Simulation Utilized?

CFD Simulation is used for optimization/malfunctioning of HVAC designs

CFD analysis data can be used for validation of diverse design parameters for example, the location, the number of exhausts and diffusers, flow rate and temperature of supplied air for meeting the design criteria. For further clarification it can be stated that, CFD simulation helps in design verification of the following systems: vestibule smoke system, displacement ventilation systems, natural ventilation systems, and raised floor system, etc. CFD model can be used for detection of HVAC designing/product malfunctioning also.

It is Used Between Alternative Systems:

In case, there is more than one option for designing HVAC system with FD Simulation one can detect which one option is the best and most efficient.

CFD is Used in Engineering Investigations:

CFD analysis of velocity, temperature, and chemical concentration allocation helps engineers in understanding the problem appropriately and offers practical ideas for the best decision about the most flawless and productive designing.

Common areas in Reality where CFD Applications are Used:

CFD modeling is used in multifaceted ways for reducing cost/testing efficiency of HVAC designs. The common areas of uses are

- General office/room simulations

- Fume hood design

- Contaminant/species simulations

- Industrial ventilation design

- Smoking lounges

- External building flows

- Fire and smoke management

- Warehouse fire simulations

- Classrooms

- Swimming pool ventilation

- Clean room simulations

- Animal and plant environments

- Enclosed vehicular facilities

- Computer cluster rooms and many more.

CFD simulation report is nowadays done on advanced software platforms like Ansys Fluent, Openfoam, Hypermesh, Ansys CFX; the use of CFD software ensures authenticity and quick turnaround time.

May be you like to read more about : Make Advance Your CFD Analysis through These Tips & Tricks

About Author: Mehul Patel specializes in handling CFD projects for Automobile, Aerospace, Oil and Gas and building HVAC sectors. He works as a CFD consultant with Hi-Tech CFD for the past 5 years and has successfully executed numerous CFD projects of high complexities. He is an expert in turbo-machinery, gas dynamics, Combustion, Fluid Dynamics, multiphase flow analysis, computational fluid dynamics etc.